G.R.C

What is GRC?

Glass Fiber Reinforced Concrete

- Its components consist of cement and sand in a high cement ratio, with the addition of crack-resistant fiberglass fibers in the form of strands ranging from 12mm to 50mm in length.

- Building technology experts agree that reinforced concrete with steel will not be suitable for the technology of the coming era, due to its heavy weight which is not suitable for skyscrapers, as well as wasting time in mixing, pouring, formwork, and treatment. Additionally, it has a short lifespan, especially in coastal cities

Fiber-reinforced concrete is considered an advanced type of concrete, and it differs from traditional reinforced concrete (GRC) in its lightweight, increased fire resistance, and enhanced mechanical, physical, and chemical properties, with reduced costs. Its tensile strength reaches up to three times that of reinforced concrete, and its lifespan is at least four times longer. It is not affected by water, moisture, acids, alkalies, sea iodine, and is non-conductive to heat and electricity. It is a highly rigid material, completely resistant to abrasion and breakage, and resistant to pollution through the possibility of creating very smooth surfaces that have no harmful effects on health.

Ingredients and Manufacturing methods

The material consists of Portland cement, sand, polymer, some binders and some special chemical additives. This mixture is strengthened very regularly with a network of alkaline glass fibers A.R fiber. It is a glass fiber very developed technologically. These fibers bear very high tensile strength, so the material gains the property of both tensile and pressure resistance. in order to combine chemically with the alkaline medium (cement medium). Then the mixture is subjected to mechanical processes that make the material very solid after drying and treatment.

The Usages

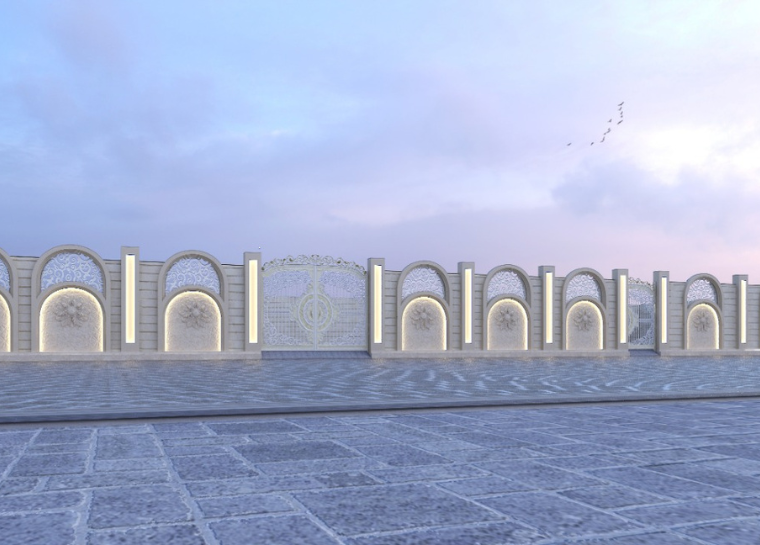

Finishing the external and internal facades of villas and towers. All external buildings ornaments are made from the material, such as cornices and classic Roman columns, as well as cladding buildings facades in any shapes, panels, niches, libraries, bathroom units, heaters, consoles, clastras, and all forms of a typical material in the implementation of building supplements and their ornaments, such as terrace balustrades, pergolas, mashrabiyas, flower beds and sunshades over the entrances, windows and bricks.